WETZIKON, Switzerland — December 10, 2024 — Loepfe has been at the forefront of mastering polypropylene clearing for years, and PRISMA is the latest proof of this expertise. As PRISMA is an evolving system, Loepfe proudly announces a further improvement in P-clearing. Designed for spinning mills facing fluctuating humidity levels, the system is proven to offer better fabric quality while maintaining the cut rate.

WETZIKON, Switzerland — December 10, 2024 — Loepfe has been at the forefront of mastering polypropylene clearing for years, and PRISMA is the latest proof of this expertise. As PRISMA is an evolving system, Loepfe proudly announces a further improvement in P-clearing. Designed for spinning mills facing fluctuating humidity levels, the system is proven to offer better fabric quality while maintaining the cut rate.

Over the past 12 months, extensive trials have been conducted, and tons of data has been collected and used to upgrade the level of accuracy in polypropylene detection. The data was used for optimization in signal processing and to offer an additional setting function specifically for spinning mills that must contend with pronounced climatic fluctuations.

Polypropylene clearing

Contamination of cotton with synthetic fibers remains a significant concern for spinning mills. Polypropylene contamination, typically stemming from bale packaging, can lead to a myriad of issues throughout the production process. These include broken needles in knitting applications, thread breakage during weaving, and visible defects in the final product after dyeing. Effective contamination clearing substantially enhances yarn quality, while overly stringent measures can negatively impact production efficiency and increase waste.

For spinners, clever P-clearing balances the need for quality yarn with the imperative to maintain operational efficiency. Loepfe’s approach combines advanced technology, precise signal processing, and tailored settings to address various production scenarios, now enhanced to account specifically for humidity fluctuations.

New climate compensation

In response to the unique demands of spinning mills operating in environments with significant humidity variations, PRISMA now features an innovative climate compensation setting. Extensive testing of this new functionality at affected spinning mills has demonstrated several benefits, including:

- Enhanced overall classification accuracy

- Improved clearing performance

- Consistent cut rates coupled with superior final fabric quality

- Same cuts and better clearing performance

The new function makes it easy to counteract the changing climate in a spinning mill. The system then takes into account the increasing humidity and calculates an average value between the standard deviation and the peak values.

By providing this enhanced climate compensation setting, Loepfe empowers spinning mills to sustain peak performance and exceptional quality, even when confronted with challenging environmental conditions.

P-Clearing Matrix

The P-Matrix allows operators to input specific parameters, starting with a pre-generated clearing curve by the Autostart function that considers the most crucial factors for optimal and efficient clearing results. By easily adjusting the settings – raising or lowering the clearing curve – operators can tailor outcomes to meet their individual production needs.

The P-Matrix allows operators to input specific parameters, starting with a pre-generated clearing curve by the Autostart function that considers the most crucial factors for optimal and efficient clearing results. By easily adjusting the settings – raising or lowering the clearing curve – operators can tailor outcomes to meet their individual production needs.

The key influences on polypropylene clearing include:

- Raw material (fiber length and short fiber content)

- Yarn count

- Twist amount in the yarn

- Yarn hairiness

- Humidity (impact on hairiness)

How to set P climate compensation

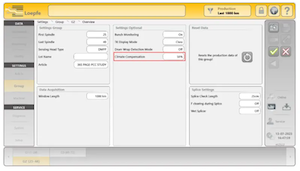

Go to Default Group Settings and set Climate Compensation to 50%. Select the checkbox Adjustable in Group to show it in Group Settings optional. This 50% will be applied to all the groups by default. The service key is required to access the Default Group Settings.

Go to Default Group Settings and set Climate Compensation to 50%. Select the checkbox Adjustable in Group to show it in Group Settings optional. This 50% will be applied to all the groups by default. The service key is required to access the Default Group Settings.

The Climate Compensation value may be influenced by the yarn count and cotton variety. It is recommended to start with a value of 50% as various trials show that the best result can be achieved between 35% and 75%.

Posted: December 10, 2024

Source: Loepfe Brothers Ltd.