TOKYO — November 12, 2025 — Teijin Limited announced today that it is using solvent-based recycling, an emerging technology, to develop high-quality recycled polycarbonate (PC) resin with quality comparable to virgin resin.

TOKYO — November 12, 2025 — Teijin Limited announced today that it is using solvent-based recycling, an emerging technology, to develop high-quality recycled polycarbonate (PC) resin with quality comparable to virgin resin.

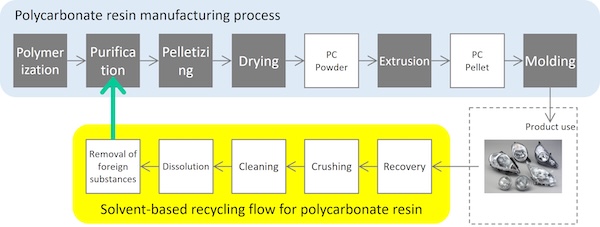

This innovative recycling method uses solvents to dissolve waste PC resin and separate pure polymers from contaminants such as surface coatings. It addresses challenges such as material degradation in mechanical recycling and high costs and carbon emissions in chemical recycling.

Expanding the use of recycled materials has become an urgent issue, particularly in Europe where the draft End-of-Life Vehicles (ELV) regulation is being considered. This directive mandates the use of recycled plastics derived from end-of-life vehicles in new car manufacturing.

Polycarbonate resin, which excels in transparency and impact resistance, is used in a wide range of applications, such as automotive parts and electrical and electronic components. However, waste PC resin may contain contaminants that negatively affect the properties, clarity and aesthetics of the recycled resin. For this reason, Teijin is developing solvent-based recycling for waste PC resin from sources such as end-of-life vehicle headlamps.

Solvent-based Recycling Benefits

Teijin processes PC resin that has already undergone conventional mechanical recycling steps such as crushing and washing, but is unsuitable for applications requiring high transparency. The company then dissolves the material in solvents and removes impurities to convert it into reusable polymers. This process allows Teijin to reclaim material whose properties, including transparency, are comparable to those of virgin PC.

The PC resin produced by solvent-based recycling has high transparency, making it suitable for closed-loop and horizontal recycling; for example, recycling discarded vehicle headlamps into new headlamps or other transparent components. In this way, solvent-based recycling helps promote adoption of recycled materials and supports compliance with upcoming regulations.

The PC resin produced by solvent-based recycling has high transparency, making it suitable for closed-loop and horizontal recycling; for example, recycling discarded vehicle headlamps into new headlamps or other transparent components. In this way, solvent-based recycling helps promote adoption of recycled materials and supports compliance with upcoming regulations.

In addition, because the solvent-based process does not involve breaking down materials to their chemical components, costs can be kept lower compared to PC resin produced via chemical recycling. Furthermore, compared to chemical recycling, solvent-based recycling involves fewer process steps, which helps to reduce CO2 emissions.

Teijin aims to commercialize PC resin produced using solvent-based recycling by fiscal year 2026. In addition, the company will continue research and development work on solvent-based recycling to further improve the quality of PC resin produced through this method.

Posted: November 25, 2025

Source: Teijin Group