SAAL ON THE DANUBE, Germany— February 3, 2026 — In times of rising cost pressure and growing quality demands, textile producers worldwide are searching for solutions that combine precision, efficiency, and sustainability. With its latest innovation, the Orthopac RVMC-20 plus, Mahlo once again demonstrates the strength of German engineering: improving proven technology to meet today’s challenges.

SAAL ON THE DANUBE, Germany— February 3, 2026 — In times of rising cost pressure and growing quality demands, textile producers worldwide are searching for solutions that combine precision, efficiency, and sustainability. With its latest innovation, the Orthopac RVMC-20 plus, Mahlo once again demonstrates the strength of German engineering: improving proven technology to meet today’s challenges.

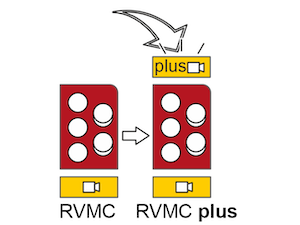

For decades, Mahlo has set the benchmark in automatic weft straightening. The new Orthopac RVMC-20 plus continues this tradition, building on the trusted Orthopac RVMC-15 while introducing a decisive technological step forward: double scanning with AI-supported control systems.

The concept relies on two detection units – one at the fabric inlet and one at the outlet. At the inlet, so-called Feed Forward Control analyzes distortions before they even reach the straightening rollers, ensuring precise positioning from the first centimeter.

At the outlet, Closed Loop Control continuously monitors the result and applies AI-based corrections in real time. This dual approach enables the system to cope even with highly variable distortions at high production speeds. The outcome is reliably straight fabric, less waste, and consistent premium quality.

Innovation without Replacement

A key feature of the RVMC-20 plus lies not only in its precision but also in its retrofit capability. Instead of requiring manufacturers to purchase an entirely new machine, Mahlo has designed the scanning module so that existing Orthopac RVMC-15 systems can be upgraded with minimal effort. By simply adding a second scanning unit, the older equipment is effectively transformed into an RVMC-15 plus – giving customers access to the latest technology without the cost of a full replacement.

The benefits of this approach are clear: upgraded machines deliver higher precision and more consistent results, while reducing waste and saving valuable raw materials. At the same time, extending the service life of existing equipment lowers capital expenditure and supports a more sustainable use of resources. In an industry facing both economic and ecological pressures, this combination of efficiency and responsibility represents a strong competitive advantage.

A Global Opportunity

With thousands of Orthopac systems already in use worldwide, the RVMC-20 plus offers a compelling proposition to textile manufacturers across markets. Every installed RVMC-15 now presents an opportunity for modernization. For customers, this means a reliable path toward improved quality and cost efficiency. For Mahlo, it strengthens the company’s position as a long-standing partner to the textile industry.

Sales Director Thomas Höpfl summarizes the philosophy behind the development: “Innovation doesn’t always mean starting from scratch. With the RVMC-20 plus, we’ve shown that progress can also mean making the best even better – smarter, more precise, and more sustainable.”

Posted: February 3, 2026

Source: Mahlo GmbH + Co. KG